Germany has long been recognized as a global leader in precision engineering and advanced manufacturing. From automotive to aerospace, and from medical devices to renewable energy, the country’s industrial backbone relies on one powerful technology: CNC machining.

But the story doesn’t end there. The future of CNC machining in Germany is evolving rapidly, shaped by digital transformation, Industry 4.0, and global competition. In this article, we’ll explore the emerging trends, the technologies shaping tomorrow’s machining industry, and what businesses should expect in the years ahead.

CNC Machining Today: A Snapshot

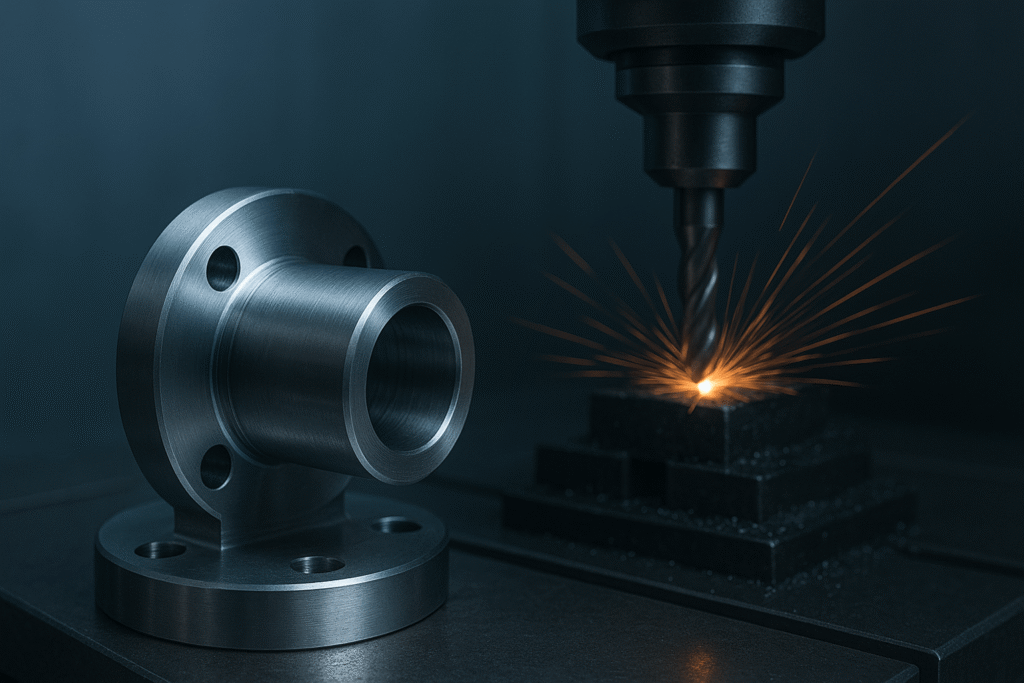

CNC (Computer Numerical Control) machining allows manufacturers to produce complex, high-precision parts from materials such as metals, plastics, and composites. Germany’s reputation for quality relies heavily on this capability.

Industries that currently depend on CNC machining in Germany include:

-

Automotive: High-performance engine parts, transmission systems, EV components

-

Aerospace: Lightweight titanium and aluminum aircraft parts

-

Medical technology: Implants, surgical tools, and diagnostic equipment

-

Industrial machinery: Bearings, gears, and custom machine components

This strong foundation now sets the stage for the next generation of CNC innovation.

Key Future Trends in CNC Machining in Germany

1. Industry 4.0 & Smart Factories

Germany is the birthplace of Industry 4.0, and CNC machining is at the heart of this movement. Factories are becoming “smart” by integrating:

-

IoT sensors for real-time machine monitoring

-

AI-driven predictive maintenance to prevent downtime

-

Cloud connectivity for data-driven decision-making

In the near future, German CNC workshops will be fully connected, self-optimizing, and highly efficient.

2. Automation & Robotics

CNC machining is becoming increasingly automated. Germany is investing heavily in:

-

Robotic arms for loading and unloading CNC machines

-

Automated tool changers for multi-task operations

-

Lights-out manufacturing (machines running 24/7 with minimal human oversight)

This not only reduces costs but also addresses the country’s skilled labor shortage by making factories more efficient.

3. Hybrid Manufacturing: CNC + 3D Printing

Additive manufacturing (3D printing) is not replacing CNC machining—it’s complementing it. In Germany, companies are using hybrid approaches:

-

3D printing for rapid prototyping and complex shapes

-

CNC machining for finishing and achieving high precision

This hybrid model is ideal for industries like aerospace and medical, where custom, lightweight, and highly accurate parts are essential.

4. Advanced Materials

Tomorrow’s CNC parts won’t just be made of traditional metals. Germany is already adopting:

-

High-strength alloys for aerospace

-

Medical-grade titanium for implants

-

Composite materials for automotive weight reduction

-

Sustainable, recyclable materials to meet EU green regulations

CNC machining will need to keep up with these advanced materials, requiring new cutting tools and techniques.

5. Artificial Intelligence & Machine Learning

AI will transform CNC machining in Germany through:

-

Process optimization – machines learn the best cutting paths

-

Defect detection – AI systems spot quality issues early

-

Cost reduction – less wasted material and fewer rejected parts

For manufacturers, this means greater competitiveness in global markets.

6. Sustainability & Green Manufacturing

Germany is committed to becoming climate-neutral, and CNC machining must align with that vision. Future machining will emphasize:

-

Energy-efficient machines

-

Recycling of cutting fluids and chips

-

Carbon-neutral manufacturing facilities

This sustainability push not only helps the environment but also appeals to global buyers who prioritize eco-friendly supply chains.

Challenges Facing CNC Machining in Germany

While the future looks bright, CNC machining faces challenges:

-

Skilled Labor Shortage: Fewer young professionals are entering precision manufacturing.

-

High Energy Costs: Germany’s transition to renewable energy has increased production expenses.

-

Global Competition: Countries like China and India offer low-cost CNC parts, pressuring German firms to focus on quality and innovation.

-

Digital Adoption Gaps: Many SMEs still lag behind in Industry 4.0 adoption.

Overcoming these challenges will determine how Germany maintains its leadership in precision machining.

Outsourcing & Global Partnerships

To remain competitive, many German companies now outsource CNC machining to trusted international suppliers while keeping R&D and quality control at home.

This is where companies like JimWell Precision – CNC Turning Parts play a vital role. By offering cost-effective, high-quality CNC machining solutions, suppliers help German industries scale without compromising precision or compliance.

The Future Outlook

Over the next decade, CNC machining in Germany will become:

-

More digital – powered by AI, IoT, and cloud data

-

More automated – using robotics and smart tooling

-

More sustainable – aligning with Europe’s green agenda

-

More globalized – balancing domestic production with international partnerships

Industries like EVs, aerospace, renewable energy, and medical technology will rely on CNC machining more than ever.

Conclusion

CNC machining is not just a cornerstone of Germany’s industrial strength—it is the key to its future competitiveness. By embracing smart technologies, automation, and sustainable practices, Germany will continue to set global standards in precision manufacturing.

For companies looking to participate in this future, partnering with reliable machining experts is essential.

👉 Explore JimWell Precision – CNC Turning Parts to discover world-class CNC solutions tailored to the needs of German industries.