Key Takeaways

- There are specialized adhesives for different materials and site conditions, making it crucial to identify your project’s specific needs before making a purchase.

- Environmental concerns, including temperature and humidity, play a significant role in adhesive performance; therefore, it is essential to account for potential climate challenges during selection.

- Surface preparation and correct application are critical to achieving strong, lasting bonds, and can be just as important as the adhesive itself in determining project longevity.

When embarking on a construction or remodeling project, the success of your build relies heavily on selecting the appropriate adhesive for the job. Adhesives serve as the unseen but vital connectors in nearly every facet of construction, whether you are working on large structural assemblies, minor trim installations, or renovations within demanding environments. From securing subfloors to affixing trim or joining dissimilar materials, each project has unique requirements that, if overlooked, can compromise the quality of the finished result. Using the right solution—such as F-26 Construction Adhesive—ensures your project holds up over time, resists environmental stressors, and maintains its structural integrity. By understanding not just the basics of adhesives but also the nuanced performance differences, you can make choices that save time, money, and frustration in the long run.

Given the wide range of adhesives on the market, understanding their formulas and strengths can help you avoid costly errors and rework. Not all adhesives are created equal, and using the wrong type can lead to failures ranging from minor aesthetic issues to catastrophic loss of structural support. The correct adhesive can mean the difference between seamless installation and recurring repairs. Selecting wisely means considering not only bonding power but also how well a formula matches your specific application, the surfaces involved, and the conditions found on your job site. Thoughtful planning at this stage helps ensure the outcome meets both aesthetic and functional expectations, while also adhering to necessary codes and best practices.

Understanding Adhesive Types

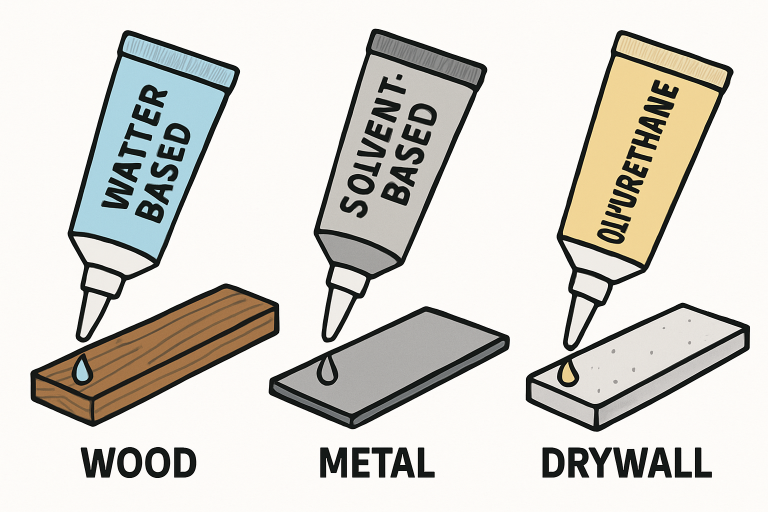

Construction adhesives are categorized into several primary types, each formulated for specific tasks and engineered to optimize performance in their designated application. Choosing among them involves considering factors such as workability, safety, drying times, and chemical resistance:

- Water-Based Adhesives: Known for their low odor and minimal volatile organic compounds (VOCs), these adhesives excel in indoor projects where air quality and health are top priorities. Their success depends on moisture evaporation, making them ideal for bonding porous substances like drywall and wood securely. However, they are less effective on slick, nonporous surfaces such as glass or PVC, since these materials do not allow water to escape and cure the bond. Their water content can also limit use in overly damp or external settings, as excess humidity inhibits curing and may weaken the adhesive’s hold.

- Solvent-Based Adhesives: Favored for their robust bonding capabilities and reliable performance in cold or humid conditions, traditional solvent-based adhesives are a staple in the construction industry. They are highly effective on nonporous substrates, metals, and plastics thanks to their chemical activation. Modern advances have reduced the strong odors and high VOC levels typically associated with older formulations, allowing current products to strike a balance between exceptional bond strength and improved environmental safety, making them more suitable for indoor use.

- Polyurethane Foam Adhesives: Gaining popularity for subfloor and structural bonding, these adhesives expand as they cure to fill gaps and provide a firm grip, eliminating the need for fasteners in many situations. Highly resilient and able to accommodate minor movements in building materials, their efficiency and versatility make them an excellent choice for high-yield and rapid application needs, especially in new construction, where speed and reliability are crucial.

Savvy builders and renovators also consider specialty adhesives designed for glass, mirrors, stone, or specific metals, each offering unique advantages in demanding situations where typical formulas fall short. These advanced products can often accommodate unusual expansion rates, chemical exposures, or even the visual clarity needed for decorative finishes.

Factors to Consider When Selecting an Adhesive

- Material Compatibility: Always verify the adhesive recommendation for the specific surfaces you’re bonding. This ensures a chemical match that provides maximum holding power and durability. A product suitable for wood-to-wood joins may not be compatible with tile, plastic, or masonry applications, so refer to the manufacturer’s datasheets and compatibility charts.

- Environmental Conditions: Job sites present challenging conditions, ranging from freezing winters to humid summers and direct exposure to sunlight. Opt for adhesives engineered to perform effectively in environments exposed to temperature swings, moisture, or UV rays. You may need to select products rated for exterior or below-grade use if your project location requires extra durability and resistance.

- Load and Stress Requirements: Structural or load-bearing areas demand adhesives with high tensile strength and flexibility, allowing them to withstand expansion, contraction, or heavy weight. Meanwhile, lighter tasks, such as decorative trim or paneling, can often rely on standard formulations intended solely for aesthetic purposes.

Application Tips for Optimal Results

- Surface Preparation: Thoroughly clean, dry, and roughen surfaces as needed to eliminate obstacles to a solid bond. Remove dust, grease, old adhesive, and lingering moisture, all of which can undermine even the best product. Even the most advanced adhesive can’t compensate for poor surface contact, so invest time in prep for professional results.

- Proper Application: Use the recommended bead size and pattern for your project’s materials, which may include continuous lines for waterproofing or spot applications for paneling. Pay careful attention to open times and curing periods as directed by the manufacturer, since rushing this step can lead to subpar bonding or visible joint lines.

- Clamping and Curing: Maintain steady pressure where possible—by clamping or adding weight—to prevent parts from shifting as the adhesive sets. This leads to a more reliable result by maximizing contact area and preventing shifting, especially with heavy or vertical installations.

Environmental Considerations

The construction industry is shifting toward sustainability, making eco-friendly adhesives a priority for many professionals and property owners alike. Innovations in chemistry and manufacturing have brought to market a wide range of high-performing products that minimize VOCs and hazardous components, supporting both worker safety and indoor environmental quality. Many of these newer adhesives also meet strict international and local regulations, ensuring compliance without sacrificing performance or longevity. By prioritizing green building practices, builders can reduce long-term risks to occupant health and contribute to industry efforts to reduce environmental impact.

Conclusion

The adhesive you choose impacts the lasting quality of your project, affecting both structural performance and aesthetic longevity. By matching your adhesive to your materials, environmental conditions, and engineering demands—and by following proper usage techniques—you secure not just your structure, but also your reputation as a builder or DIY enthusiast. Each project deserves the best solution for long-term durability and peace of mind, so take the time to research, select wisely, and apply with precision for results you can trust.